RTK-GPS simplifies operation and drastically decreases time and costs involved in construction surveys.

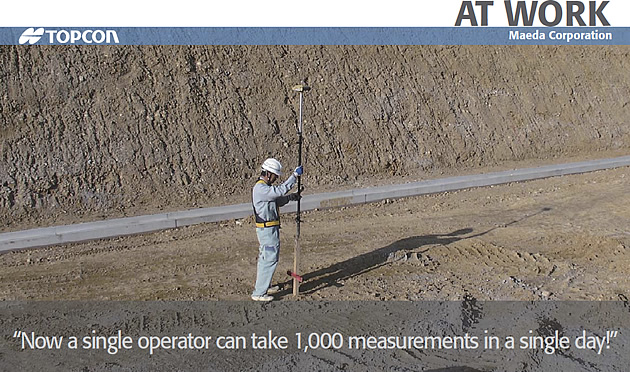

Maeda Corporation has been involved in the construction of some of Japan’s most well-known structures. We visited their Ohyabu worksite in Ina County, Wakayama Prefecture, an area that features numerous steep slopes. Site engineer Mr. Konishi explained, “At this site, we are mainly using GPS for initial site surveys and as-built checks.”

Previously, they hired contract surveyors to do the work using total stations. Now, according to Mr. Konishi, “We don’t need to contract out. Using this technology, one person can take around 1,000 measurements in a day.” Regarding the benefits of making the switch to GPS, he says, “In addition to the higher efficiency, the reduction in labor costs is one of the major benefits.” As another merit of GPS, he mentions the fact that “far more points can be measured with a single base station setup. With a total station, we had to change the instrument setup more often to measure a wide area.”

Before they made the transition to GPS, Topcon gave Mr. Konishi a demonstration, enabling him to experience a variety of GPS measurements, including accuracy checks of reference points, road centerline stakeouts, and cross-sectional surveys. The site for the demonstration was in a mountainous area with steep inclines and a restricted overhead field of vision. This meant that there were a number of points at which it was difficult to receive GPS signals ” less than ideal conditions for GPS measurements. After measuring a number of points, however, Mr. Konishi found himself getting used to the operation of the unit and his measurement speed increased. He was impressed and said, “Initial site surveys could be done in a lot less time with GPS than a total station. And it’s great that one operator can take measurements.” Now, having actually introduced the unit, he tells us that his expectations have been fulfilled. He added that “in future, I’d like to use GPS in various stakeout and positioning applications,” and that to enable this, he hopes for more lightweight GPS systems to increase mobility.

Today, every worksite needs to increase the efficiency of its operations. Mr. Konishi says, “Our GPS system allows us to do our own measurements, which reduces contracting costs, and we can do those measurements just when we need to, so the administrations we do projects for also rate it highly.” He is also planning to propose new ways of using GPS on the site. “I think that by increasing the level of our survey technology, we can achieve even better results in the Assessment of Contract Construction Projects*,” he says, considering the applications of GPS with an eye on the future.

* These are results based on the “Guidelines for the Assessment of Contract Construction Projects”, established by the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) in 2000. For projects with a value of 5 million yen or more, the Regional Development Bureau of MLIT evaluates 1) the quality of the completed structures, 2) the level of technical difficulty of the project, and 3) the details of proposals for Value Engineering (VE) and their outcomes, and the evaluation results are compiled. This is an important element in the Comprehensive Evaluation Method for Public Works Projects, in which successful tenderers are selected not only on the basis of cost, but also on a multi-faceted evaluation of their previous results, their technological level, and other factors.

COMPANY:Maeda Corporation