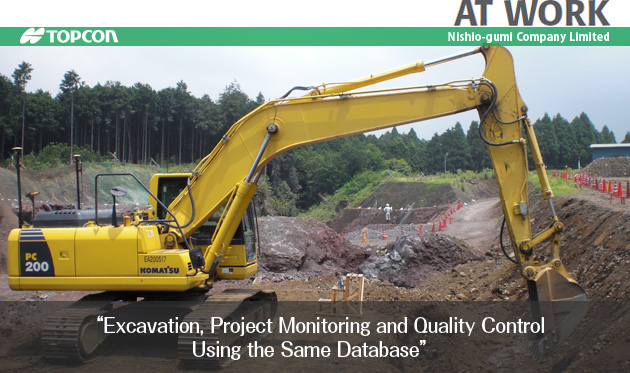

Topcon 3D-MC and GPT-9000A Streamlined Excavation Procedures of Sand Basin in the Middle of Steep Slope

Nishio-gumi Company Limited is a general contractor in Fuji-city, Shizuoka, Japan. Despite a relatively small organization, Nishio-gumi is growing its business by introducing new technologies that differentiate the company from much larger construction companies. In addition to general building construction projects, the company had secured a number of government projects, including land preparation, coastal revetment and erosion control project in their region.

Picture:Scene of site tourNishio-gumi used the Topcon 3D-MC excavator guidance system (X63) and the GPT-9000A robotic total station for a sand basin construction at the foot of Mt. Fuji. The Chubu Regional Bureau of MLIT*1 has designated this project as a model for application of ICT-Aided Construction*2. The volume of dirt excavation exceeded 42,000 cubic-meters (450,000 cubic-feet). The 3D-MC excavator was used for about 80 percent of the ground excavation, with 3D survey data collected by the GPT-9000A.

Located in the middle of a steep slope, this sand basin is designed for the purpose of sediment controls to prevent soil, sand and water from flowing into the coast. The Fuji Sediment Control Office of MLIT conducted a site tour to show the actual application of machine control technology at this unique construction site. This tour was picked up by the local press, showing high interest in ICT-Aided Construction.

Akihiro Endo, site representative of Nishio-gumi, said “With the Topcon 3D-MC, we can work solely with 3D design data without using stakes and strings. The GPT-9000A enables one person to carry out all survey tasks. Both technologies dramatically reduced time and labor.”

“With the Topcon system, design data and as-built survey data can be shared in XML format among 3D-MC, field controller and other computers on site. This allows us to perform everything from excavation to project monitoring, and to quality control using the same database, increasing overall work efficiency and quality.”

“Topcon 3D-MC and GPT-9000A will also increase our corporate evaluation points which is a definite advantage when bidding on a public project,” Endo said.

*1 MLIT: The Ministry of Land, Infrastructure, Transport and Tourism

*2 ICT – Aided Construction: Construction methods that make use of Information and Communication Technologies (ICT) to increase work efficiency and quality. Machine control system is one of the representative examples.

COMPANY:Nishio-gumi Company Limited