Topcon Compaction Control System Dramatically Increases Work Efficiency and Quality of Earthworks.

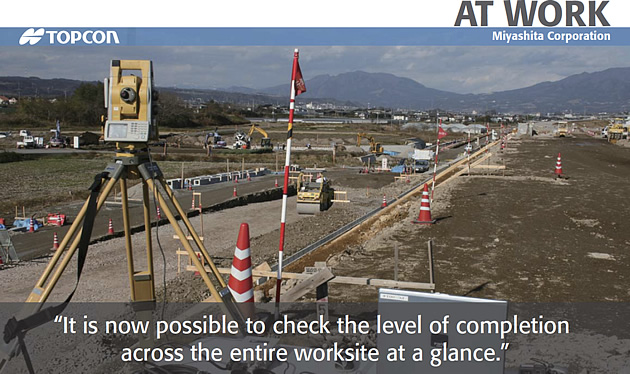

Miyashita Corporation, a well-known construction and land development company in Gunma Prefecture, introduced the Topcon Compaction Control System, with the Robotic Total Station GPT-9000A as its core sensor, to help them increase the quality and efficiency of earthworks for the construction of a bypass road in the prefecture. The worksite was 1,520 meters (approx. 1 mile) in length, and represented 36,000 cubic meters of soil volume. Conducting a soil density test using the conventional sand replacement or radioisotope (RI) methods would have involved a considerable amount of time and effort. “Using the conventional method, we would have had to take soil samples from three points for each 500 cubic meters, for a total of 216 points, and conduct soil density tests on them all. Assuming that the test for each point would take an average of one hour, we would have spent 216 hours on soil density tests alone. Introducing the new Compaction Control System was therefore essential to us in terms of increasing our work efficiency,” says a Supervisory Engineer in the company’s Construction Division.

He explains the merits of the system as follows: “The greatest benefit of the system is that it makes it simple for us to grasp the status of the soil across the entire worksite. Instead of conducting soil density tests using conventional methods, we can understand the level of completion through the number of times the soil has been compacted. Roller-compactor operators can constantly check their own trajectory and the number of times they have compacted a specific section on a monitor, and that makes it easy to achieve uniform compaction of the entire worksite. As a result, you can significantly increase work efficiency, and quality also improves. Miyashita Corporation fitted the system on its earthmoving equipment, and implemented the project with trained operators in control of the machinery.

MLIT is proceeding with the introduction of “Information Integrated Construction” in order to increase work efficiency and quality. As part of this initiative, the Ministry is formulating “Guidelines for Soil Compaction Management using TS and GPS”. This engineer goes on to discuss a further twofold benefit of introducing the system. GPT-9000A “We believe that our use of the Topcon Compaction Control System is a factor that is taken into account when we tender for a job, and that it distinguishes us from our competitors. The number of highly experienced roller operators is declining in our industry, and so we see the introduction of the system as essential for us. Another merit of the system is that the current system uses a total station rather than GPS, and so it complies with the “Guidelines for Project Management using Total Station,” formulated by NILAM. “

*1 MLIT: The Ministry of Land, Infrastructure Transport and Tourism

*2 Construction methods that make use of various information technologies, including 3D measurement data obtained by GPS and Total Stations, to increase work efficiency and quality. Machine control systems are a representative example.

*3 NILAM: The National Institute for Land and Infrastructure Management. A subsidiary of MLIT.

COMPANY:Miyashita Corporation