“We decided to own a robotic total station because we can use it both for machine controls and for as-built survey.”

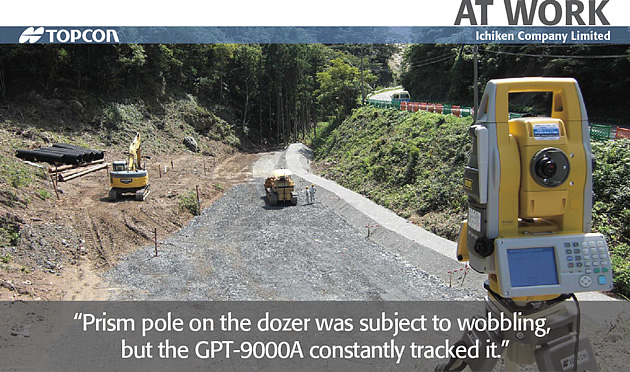

Ichiken Company Limited recently undertook a road construction project in Tsushima Island, Nagasaki, Japan. They utilized the Topcon GPT-9000A robotic total station as a sensor of a compaction machine control system.

A few months before Ichiken started the project, Topcon conducted a CPDS*1 seminar instructing the company’s engineers on the operation of robotic total station and machine control system. Ichiken encourages its personnel to participate in CPDS seminars to earn scores which give them advantages in public work biddings. At that seminar, they were “deeply impressed by Topcon’s advanced technology,” Hideyuki Abiru, a chief engineer of Ichiken, said.

Initially, they planned to rent a total station. “But we decided to own it,” he said, “because we came up with an idea to use the robotic total station both for machine controls and for as-built survey. It would give us a significant advantage since these two technologies are registered to the NETIS*2.” The road construction site was 110 meters (360ft.) in length with 10 meters (33ft.) of maximum landfill depth. “We set up the total station at a location where it could view the entire construction area. The prism pole on the dozer was subject to wobbling, but the GPT-9000A constantly tracked it. Recovery of prism lock was also very smooth and we could minimize downtime,” Abiru said.

Ichiken was the first contractor to introduce a compaction control system in Nagasaki. He continued, “The regional development bureau, an ordering party, gave us a very high score at the interim inspection that was worth the local governmental prize in construction achievement. It motivated all of us to pursue further technological innovation.”

“We will make the best of GPT-9000A, not only for machine controls, but also for as-built survey in compliance with the guidelines of NILAM*3. We are confident that these new technologies will further strengthen our position,” Abiru said.

*1 CPDS: ‘Continuing Professional Development System’ managed by JCM (Japan Federation of Construction Management Engineers Associations)

*2 NETIS: ‘New Technology Information System’ conducted by MLIT (The Ministry of Land, Infrastructure, Transport and Tourism)

*3 NILAM: The National Institute for Land and Infrastructure Management, a subsidiary of MLIT

COMPANY:Ichiken Company Limited

TOPCON PRODUCT:

Robotic Total Station GPT-9000A