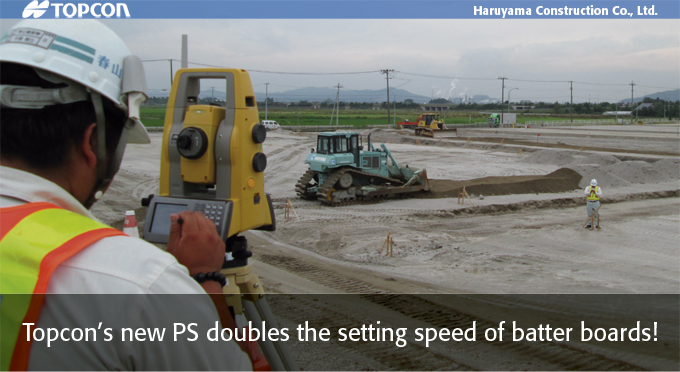

PS proves ‘high performance’ in the field of reconstruction projects in Tohoku

The Haruyama Construction Co., Ltd. located in Iwanuma city, Miyagi prefecture, is a company known for its expertise in the areas of civil engineering and paving projects. The company undertakes construction projects for the collective relocation of citizens affected by disasters. The company’s first project was laid over the three prefectures disrupted by the Great East Japan Earthquake. By utilization of the Topcon PS Total Station with Auto Collimation technology, Haruyama shorten the speed of the work performed substantially. The Topcon PS includes construction-oriented onboard software “Doboku-Kihon CE.”

Makoto Mori, manager of company’s construction department, said, “We are responsible for filling the dirt on about 10ha out of total 20ha to develop an area for 173-lot area for residential dwellings.”

After the earthquake, the company purchased four Auto-Collimation type total stations, and the company added a PS to its inventory for this project. Makoto Kanayama, general manager of the General Planning Office, said, “Unfortunately, our total stations and data collectors, we previously owned, were destroyed by the earthquake. Prior to re-acquiring our precise positioning instruments, we actively participated in CPDS (Continuing Professional Development System) seminars and onsite demonstrations to obtain information to choose the most effective one for our future works. Then, we decided to buy motor-drive total stations for increasing efficiency and productivity, and we intended to use mainly for as-built checks. We selected Topcon’s PS because we were impressed with the exceptional operability of Topcon’s motor-drive total station.”

Ryu-ichi Nakamura, who works in the company’s construction department and is assigned as site agent of this project, stated, “There are so many merits in the PS. First of all, auto collimation is very accurate. We used to level all the points of batter boards, and had to turn the points repeatedly where the height difference exceeded tolerance. Currently we use a level for some important points, but most of the points are measured by PS due to its ability of accurate auto collimation and high accuracy measurement.”

Nakamura continues, “Secondly, we made it possible to speed up stakeout jobs because we can avoid the time to manually adjust and verify the angle values; PS turns to the correct direction horizontal angle of stakeout point by its motor-drive control, without any error.” He said the data collector also is very useful. “If you change the layout point location, you can calculate and yield the points of batter boards in the field, without going back to the office. The number of batter boards we can set doubles in the same timeframe!”

Takeshi Hiratsuka, who works in the same construction department, “We have, on

occasion, had a hard time to keep the project on time in the short at another job site. Now we can make accurate measurements, and accomplish them on time in the schedule, thanks to efficiency improvement we can achieve with the auto-collimation total station.″

Finally, Mr. Kanayama said, “We would liketo complete the construction project as fast as possible for the people who are living in temporary houses. The project schedule is very tight, but we can rely on PS to finish the tasks quickly, efficiently and accurately.″

Managing Director

COMPANY:Haruyama Construction Co., Ltd.

TOPCON PRODUCT:

Power Station PS